Space

The ACC will be housed in a 16,000 sq. ft. UW facility available at Sand Point (Magnuson Park Building 5A, 7561 63rd Ave NE, Seattle, WA, 98115). This space includes manufacturing floor, classroom and presentation space, grad student suite, fully-equipped conference room, technical office, and (shared) industry-user office. The center has equipment for research, validation and acceleration of composite materials, structures, software and production. Additionally, the center facilitates composites educational and outreach efforts. The ACC facility equipment will be available as a cost center for other UW and external users.

Equipment

ACC users have broad access to equipment needed for composites research such as automated fiber placement system, autoclaves, ovens and hot presses for specimen fabrication, router and fabric cutters for fabricating the conducting embedded layers; various machine tools such as molding machines and CNC machines, electromechanical test frames for static tests and servo-hydraulic test frames for cyclic fatigue tests; and the associated test frame accessories such as load cells, and data acquisition systems.

Additionally, ACC users can leverage facilities at the UW such as the Molecular Analysis Facility (MAF), located on the ground floor of the Molecular Engineering and Sciences Building on the UW campus, the Instrumented Test Facility maintained in the UW Mechanical Engineering Department, the Advanced Material Characterization lab in the UW Materials Science and Engineering Department, and the Advanced Testing Lab maintained in the UW Aeronautics and Astronautics Department.

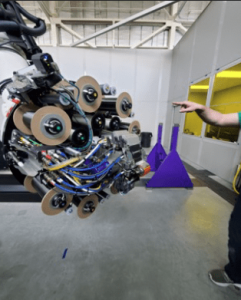

AFP System

The ACC provides a robotic Automated Fiber-Placement (AFP) system made by Electro-Impact (EI), capable of manufacturing high-contour (complex) components, which can adapt to different geometries and part sizes. The AFP machine, acquired by ACC through a public-private partnership between WA-state and Composites Industries, is capable of laying thermoset, thermoplastic, or dry fiber material form. The EI AFP system includes a Standard Modular Process 8-Tow Head (end-effector) technology. Electroimpact’s Variable Spot Size Laser heater enables high-power heating required for thermoplastic materials. This laser has a very high energy density, allows microsecond changes in the energy applied for precision temperature control, and has optics to shape the beam to accurately cover the width of the composite tow. Positioning is achieved using an Electroimpact modified and upgraded Kuka KR1000L750 Titan combining high speed, high payload, and long reach for flexible motion. The robot is track mounted for an additional 7th axis. A Vertical Turntable for complex parts. The system uses a Siemens 840D controller and industry standard VCP programming from CGTech. Additionally, the ACC has AFP simulation software from CGTech called VCS. VCP and VCS have post processing capability that is completely open to the user to facilitate research using the AFP robot.